STORY

Moved from being

a tool-and-die shop to a

high-volume component

manufacturer for OEMs

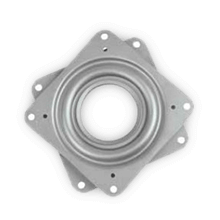

Worked with cabinet

manufacturers to design

the lazy susan bearing

Computerized

auto-order processing

Introduced a cellular

structure in manufacturing

Triangle Manufacturing

An Industrial Bearings & Metal Components Manufacturer

Engineering Is in Our DNAOver 100 years ago, Frank Sullivan took a giant leap –the kind that only the entrepreneurial engineer will make.

From the shop room floor at what was then Oshkosh Truck Corp. (and is today known as Oshkosh Corporation®), he ventured out on his own to establish Triangle Manufacturing Company in 1922.

Originally conceived as a tool and die shop, Sullivan followed his instincts and customer base, building the company from its humble roots into what has become one of the largest U.S. metal components and bearing manufacturing companies. Triangle Manufacturing’s product offering is diverse—from spherical plain bearings and rod end bearings to linkage assemblies and blower motor belly band brackets. Today, our customers—from small-and mid-sized manufacturers to Fortune 500 companies—span the globe.

And, Sullivan’s legacy of thinking entrepreneurially, engineering creatively and delivering reliably, lives on. It's on our DNA.

Bearing Engineering

know-howToday—as in 1922—Triangle Manufacturing Company is run by engineers, for engineers. We’re here to solve your problems, no matter how complex. And we build our products – from plain bearings to rod end bearings – to last. We want our designs to work just as well years from now as they do today

What does our product lineup include?

Spherical Bearings

Industrial Rod End Bearings

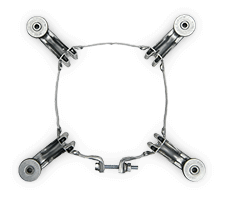

HVAC Spider Blower Brackets

Lazy Susan Bearings

Threaded Rods

And if you don’t find the exact product you need to drive your design over the finish line, we’ll customize components for you. Our work lies in finding creative solutions to engineering challenges. If you have goals to meet or problems to solve through design, engineering, manufacturing and delivery processes, we invite you to schedule your free consultation with our expert.

Throughout our over 100-year history, we’ve continued to invent and innovate, both our products and processes, to provide you with reliable components and engineered solutions that keep you ahead of your competition.

introduced light-out manufacturing technology

Used our first production robot

ISO: 9001 2008 certification

ISO: 9001 2015 certification

A metal forming company

with creative problem-solvingWe know you need to move fast. That’s why we’ve built our processes to:

Engineer solutions quickly

Develop rapid prototypes

Manufacture our own parts

(rather than relying heavily

on third-party suppliers)

Our team is a collaborative partner, equipped to bring new ideas to the table. When developing solutions, we work with the entire team, including engineering and purchasing, to ensure our solutions and pricing align with organizational goals.

How Bearing Engineering

helps our customers

The advantage of having over 100 years of manufacturing experience: We can draw on our past successes to bring you better solutions, faster. Consider this customer’s challenge:

In the midst of developing a solar application, our customer encountered a puzzling challenge. With fierce weather conditions battering the installation site, a brass assembly was required. Because steel is not natively pliable, the customer had struggled to find a manufacturing partner who could deliver. When they brought the challenge to Triangle Manufacturing Company, we tapped into our bearing engineering DNA. Drawing from our vast archive, we found product research for a similar problem, solved decades earlier. We called up the design, developed the prototype and showed the customer a solution that works.