Triangle's experienced engineers are ready to help determine the exact specifications needed for your application. We can handle your design from start to finish. Contact Triangle Manufacturing today and consider it done.

SCHEDULE A FREE CONSULTATION

Triangle is an American manufacturer of industrial rod end bearings. Triangles rod end bearings supply a cost-effective, low-maintenance solution for the following applications: lawn and garden, HVAC, agriculture, heavy-duty vehicles, recreational vehicles, solar, automation, conveying, food processing, and manufacturing.

Triangle Manufacturing offers spherical rod end bearings to fit a wide range of applications in agriculture, lawn and garden, HVAC and air handling, automotive, recreational industries, construction, manufacturing, pulp & paper, power generation, mining, water treatment, aerospace, quarrying and mining. Part drawings available in PDF and STEP formats - find the bearing you need and click “Download Drawing”. Reduce SKUs, save time and reduce costs with Triangle’s rod end linkage assembly. Learn the advantages our full linkage solution. Let us put our metal fabrication and engineering expertise to work for you. Learn more about our custom solutions. Triangle Manufacturing has the engineering experience and capabilities to help you bring products from conception to production. Customers who purchase rod end bearings often benefit from Triangle Manufacturing's Linkage Assemblies. Nearly 100 years ago, Frank Sullivan took a giant leap –the kind that only the entrepreneurial engineer will make. From the shop room floor at what was then Oshkosh Truck Corp. (and is today known as Oshkosh Corporation®), he ventured out on his own to establish Triangle Manufacturing Company in 1922. At first glance, the engineering capabilities among manufacturing companies may seem largely the same. So, what sets Triangle Manufacturing apart? The difference is in our DNA. Our company was built by engineers, grown by engineers and is led by engineers today. Since our start in 1922, we’ve been a stamped metal component and bearing manufacturing company run by engineers for engineers. We foster a culture of innovation throughout the entire company – from sales to engineering to manufacturing and shipping. Have you ever tried to fit a spherical plain bearing or linkage assembly into a new design, only to find that it’s like putting a square peg into a round hole? You contact your bearing or linkage supplier hoping their custom metal fabrication and stamping expertise will help you address the problem AND meet the tight deadlines you face.

Industrial Rod End Bearings

Triangle Manufacturing is a supplier of Industrial Rod End Bearings made in the USA

Rod End Bearing Options:

Other Rod & Linkage Products

![]()

About Triangle Manufacturing

![]()

Bearing Engineering - It’s in Our DNA

![]()

Innovators Focused on Your Success

![]()

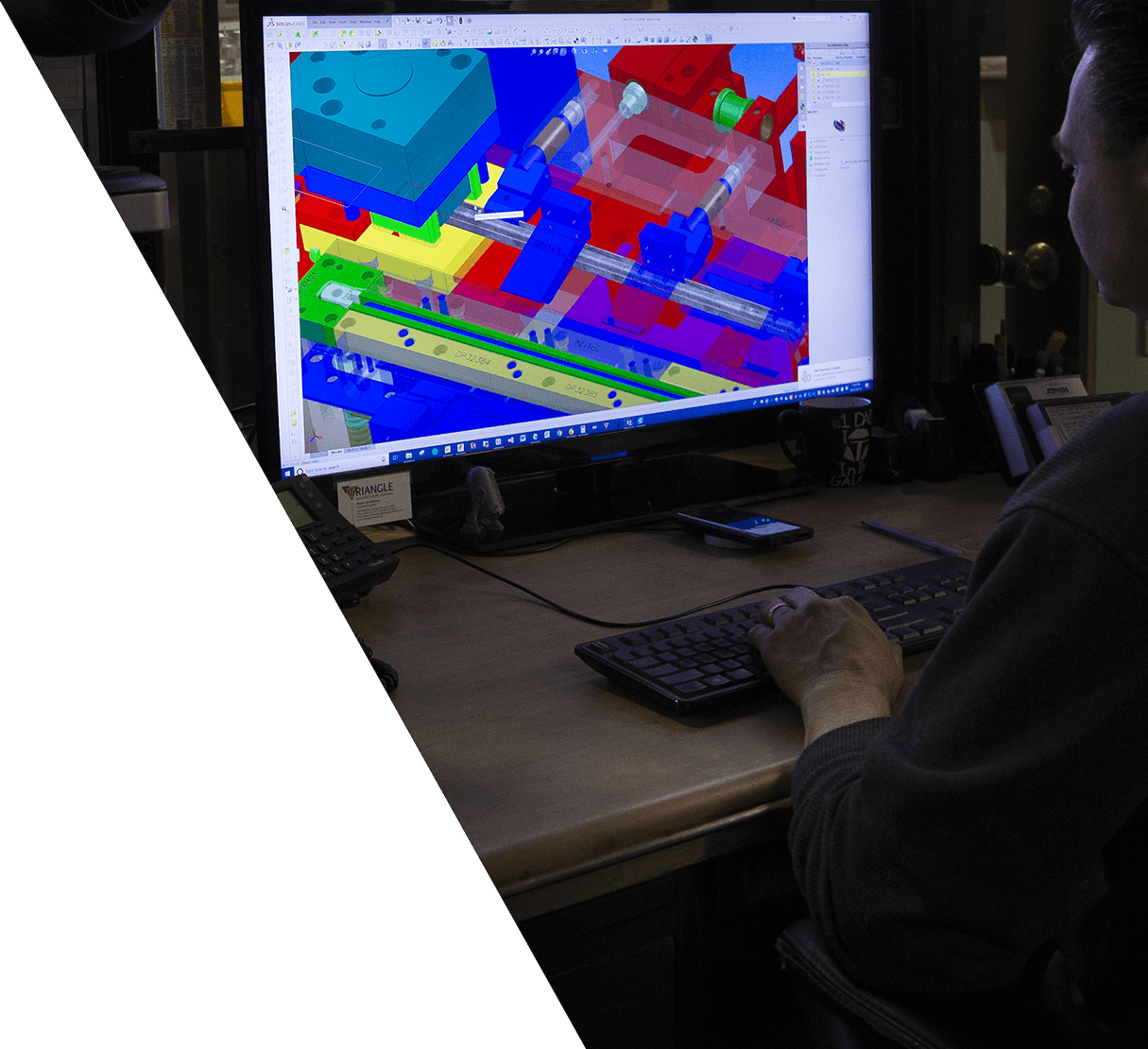

Bearing Engineering Design Process