Double Ended Threaded Rods Save OEMs time and Money

"We noticed manufacturers spending extra time assembling rod ends and threaded rods together," explained Don Brandner, Director of Sales and Marketing. "We saw this as an opportunity to help our customers save time and money on the production floor."

Oshkosh, Wisconsin (October 13, 2020)

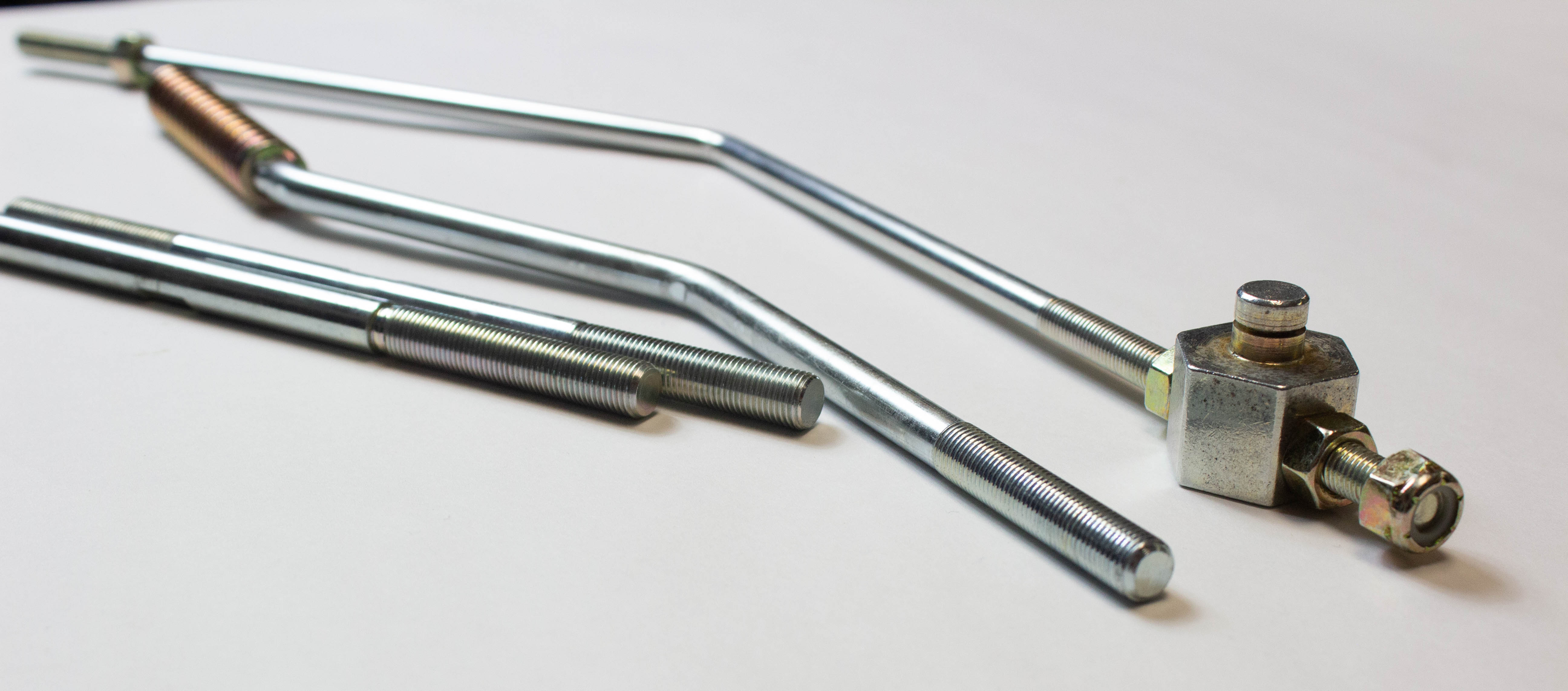

Triangle Manufacturing Company, a Wisconsin based metal component and threaded rod manufacturer, now offers double ended threaded rods to original equipment manufacturers.

"We noticed manufacturers spending extra time assembling rod ends and threaded rods together," explained Don Brandner, Director of Sales and Marketing. "We saw this as an opportunity to help our customers save time and money on the production floor."

Triangle is now manufacturing spherical rod ends and threaded rods in-house. Spherical rod ends and threaded rods can be purchased as separate components or together as a linkage assembly. The advantages of purchasing an assembly rather than separate parts include:

- Reduced SKUs & Supplier Management - Purchasing separate components, such as spherical rod ends, rods and fasteners requires management of separate SKUs and suppliers. Triangle's rod end linkage assembly results in one managed SKU and one supplier.

- Eliminate Time on Assembly - Triangle's threaded rod end linkage assemblies allow your production team to instantly install onto the application. If you purchase separate parts, this takes time for your team to assemble each part together before installing onto the application.

- Lower Per Piece Cost - Purchasing a rod end linkage assembly from Triangle is often more economical than purchasing separate components individually.

While the rod end linkage is one of the reasons Triangle decided to roll cut threaded rods, we also saw the opportunity to supply threaded rods and threaded rod ends for other application needs as well.

5/16-24 and 3/8-24 are our popular thread sizes, but we can also supply rods that range from 1/4" to 7/16". They are available in low carbon steel, stainless steel and aluminum. Rod lengths can vary from 4" to 48".

As a threaded rod manufacturer, Triangle also provides custom rod options, including: rod bending, wrench flats, flattening ends and drilling mount holes, plating options, addings springs and more

Common applications that use Triangle's rods, threaded rod ends and rod end linkage assemblies include: solar trackers, zero-turn and stand-behind mowers, production equipment, light-duty vehicles and HVAC louvers.

To learn more about Triangle's threaded rod capabilities or rod end linkage assembly, contact us today or call directly at (920) 235-3710.