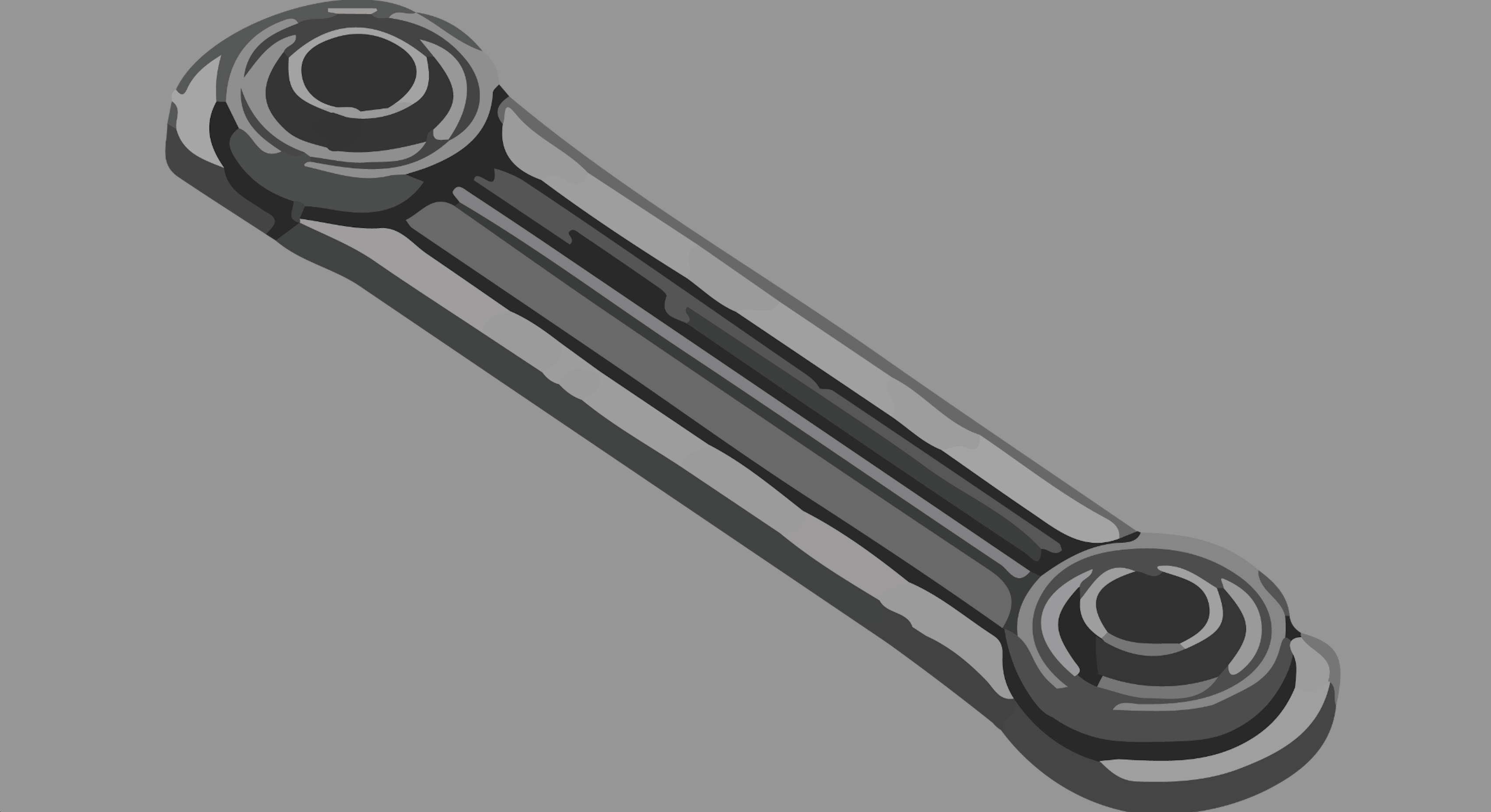

Heavy Duty Fixed Metal Linkage Replaces Adjustable Rod Linkage Assembly

Triangle Manufacturing’s team was on a visit to a lawn mower manufacturer when they noticed the heavy use of adjustable rod linkage assemblies on their zero-turn lawn mowers.

Triangle Manufacturing’s team was on a visit to a lawn mower manufacturer when they noticed adjustable rod linkage assemblies were heavily used on their zero-turn lawn mowers. One of Triangle’s application engineers suggested using a fixed metal linkage instead. He did not see the necessity of using an adjustable rod linkage assembly on this part of the zero-turn lawn mower. He also knew that switching to a fixed metal linkage would save the manufacturer a ton of time and cost.

FIXED METAL LINKAGE VS. ROD LINKAGE ASSEMBLY

This lawn mower manufacturer was facing a labor shortage like much of the nation. They were currently having employees assemble the adjustable rod end linkages while on the line, prior to putting the part on the mower. Triangle’s fixed metal linkage is a full assembly and can be taken right to the line for more efficient assembly times during production. This allowed the lawn mower manufacturer to shift employees around to short-staffed areas..

5 BENEFITS OF TRIANGLE'S METAL LINKAGE ASSEMBLY

- Decreasing SKUs: The rod linkage assembly on the zero-turn lawn mower had jam nuts and was accounting for five different SKUs the buyer was responsible for purchasing. By getting the fixed metal linkage from Triangle, this dropped down to one SKU and resulted in saved time management by only dealing with one supplier.

- No plating required: Triangle's metal linkage rod is stamped from galvanized steel, which eliminates the need for plating. This results in time saved from sending the assemblies to platers and additional cost-savings.

- Self-lubricating bearings: Triangle's metal linkage assembly is manufactured with two sintered spherical plain bearings. Sintered bearings are self-lubricating, which results in less maintenance and a longer life-span. View more benefits of sintered bearing material.

- Strong static load: The spherical plain bearings manufactured with the metal linkage have static load ratings from 7,000 lbf to 24,000 lbf. View all static load data of Triangle's spherical plain bearings.

- No tooling costs: This metal rod end linkage was custom made for this lawn mower manufacturer with no tooling costs associated with the switch.

Triangle understands that engineers prefer adjustable rod linkages during the design phase because spherical rod ends are an off-the-shelf product and they can cut a linkage rod to any needed length. That is why we have equipped our engineering department to turnaround samples quickly, so we can get a prototype to your doors in time for testing.

As highlighted above, there are many benefits of switching to a fixed metal linkage when an adjustable rod linkage is not necessary. Triangle Manufacturing is always looking out for ways to improve your applications and simplifying tasks in your production lines.

Whether you are looking for a custom linkage assembly or ideas on how to simplify a part with a lot of management tied to it, let’s talk. We are always happy to help! Complete our form on our contact page or call (920) 235-3710.