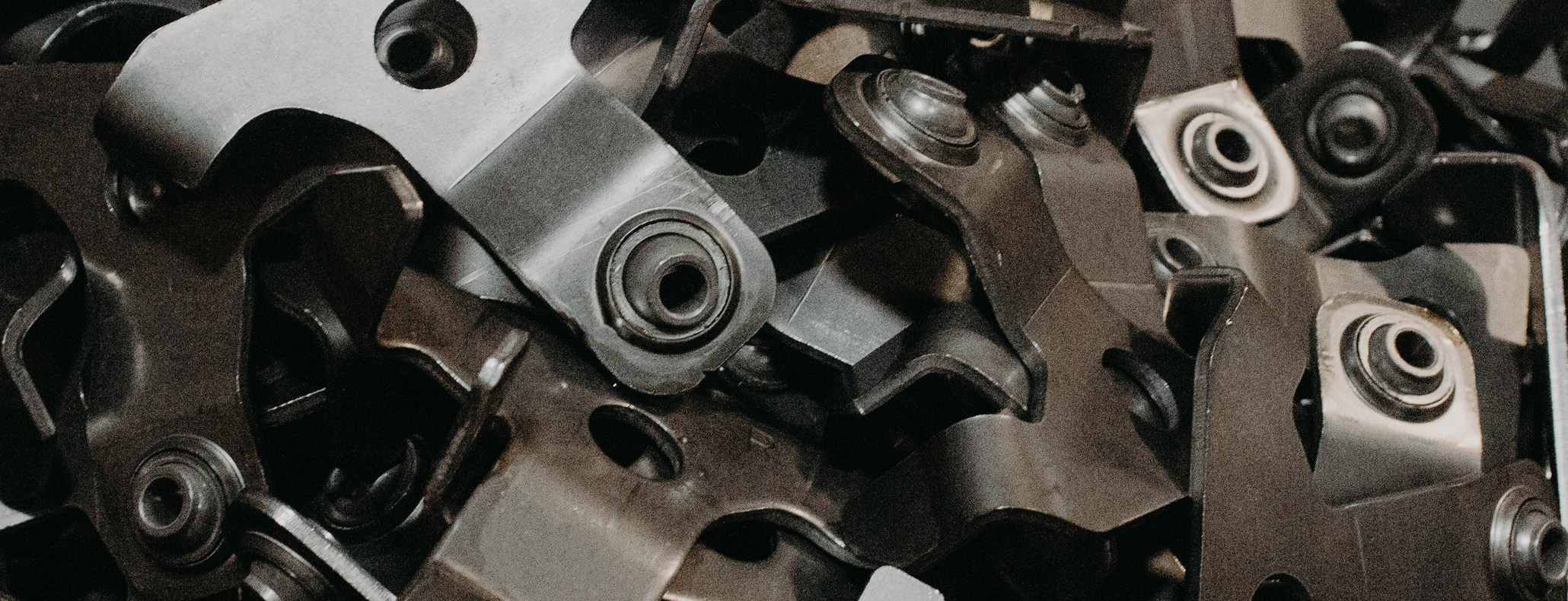

Lawn Mower Linkage Application

Riding lawnmowers take a beating. Traveling over the uneven terrain of our yards week after week wreaks havoc on the mowers’ steering assemblies. We designed a self-aligned lawn mower bearing assembly that’s ideal for this situation. It effortlessly handles these misalignments, as well as the dirt and debris, that are a part of every lawn mowing operation.

Taking the complications out of a steering linkage system

Riding lawnmowers take a beating. Traveling over the uneven terrain of our yards week after week wreaks havoc on the mowers’ steering assemblies. We designed a self-aligned lawn mower linkage assembly that’s ideal for this situation. It effortlessly handles these misalignments, as well as the dirt and debris, that are a part of every lawn mowing operation.

The request

During the design for a new riding lawn mower, our customer contacted our sales team about desinging a metal linkage assembly on one of their new lawn mowers. Their goal was to stop the steering wheel from turning too far. The design included three parts of the steering linkage system: a linkage, another metal piece attached to the wheel base and a bearing attached to the linkage that controlled the steering column.

Our solution

Once we reviewed the complete mower design, our team of engineers provided the lawn and garden equipment manufacturer with a solution that reduced the number of components needed from three to one. This solution reduced:

- Costs

- Manufacturing time

- The number of SKUs

How did we do it?

As a company led by engineers for engineers, we are always looking for ways to streamline manufacturing processes. Using our depth of design knowledge, we fulfilled the customer’s needs with just one piece—a bracket stamped from metal. We used heavier gauge material that we bent to make it stronger than the weld points used in the customer’s design. Then we integrated a spherical plain bearing instead of having the bearing attach externally with two bolts. We consolidated the spherical plain bearing into the existing plate, eliminating the need for in-house assembly.

The lawn mower linkage assembly was easy to test, helping us ensure its quality and longevity.

Metal stamping vs. machining: Save time, money

In a case like this, our engineering process proved that precision metal stamping is the preferred solution over machined components. If you need large quantities of the same product, stamping offers many benefits:

- Components will be consistent time after time

- Per-piece setup and labor costs go down the more you make

- Because the process is automated (no fingerprints touch our stamping products from raw material to packaging), it’s easy to modify parts or include value-added assemblies

- There is less material waste, resulting in cost savings

Thanks to the stamping process, we manufactured the product quickly. This gave us the flexibility to easily adjust to customer demands and provide just-in-time delivery.

Whether you have a lawn mower linkage application or another component for a different market, our engineers are ready to work side-by-side with you to develop the most cost-effective, longest-lasting solution.

If you want ways to reduce the overall costs in your design, contact us for help by calling (920) 235-3710.