Triangle's Metal Linkage Assembly Results in Cost-Savings

During a conversation with a turf-equipment manufacturer, Triangle realized they were laser-cutting a 1/4" thick narrow piece of metal for a mower deck application. This metal piece also had two holes machined out to attach the hand controls to the deck.

There were many problems with this manufacturer's current technique for this part. This narrow piece of metal was taking up too much space, there was a lot of binding and too much noise during operation.

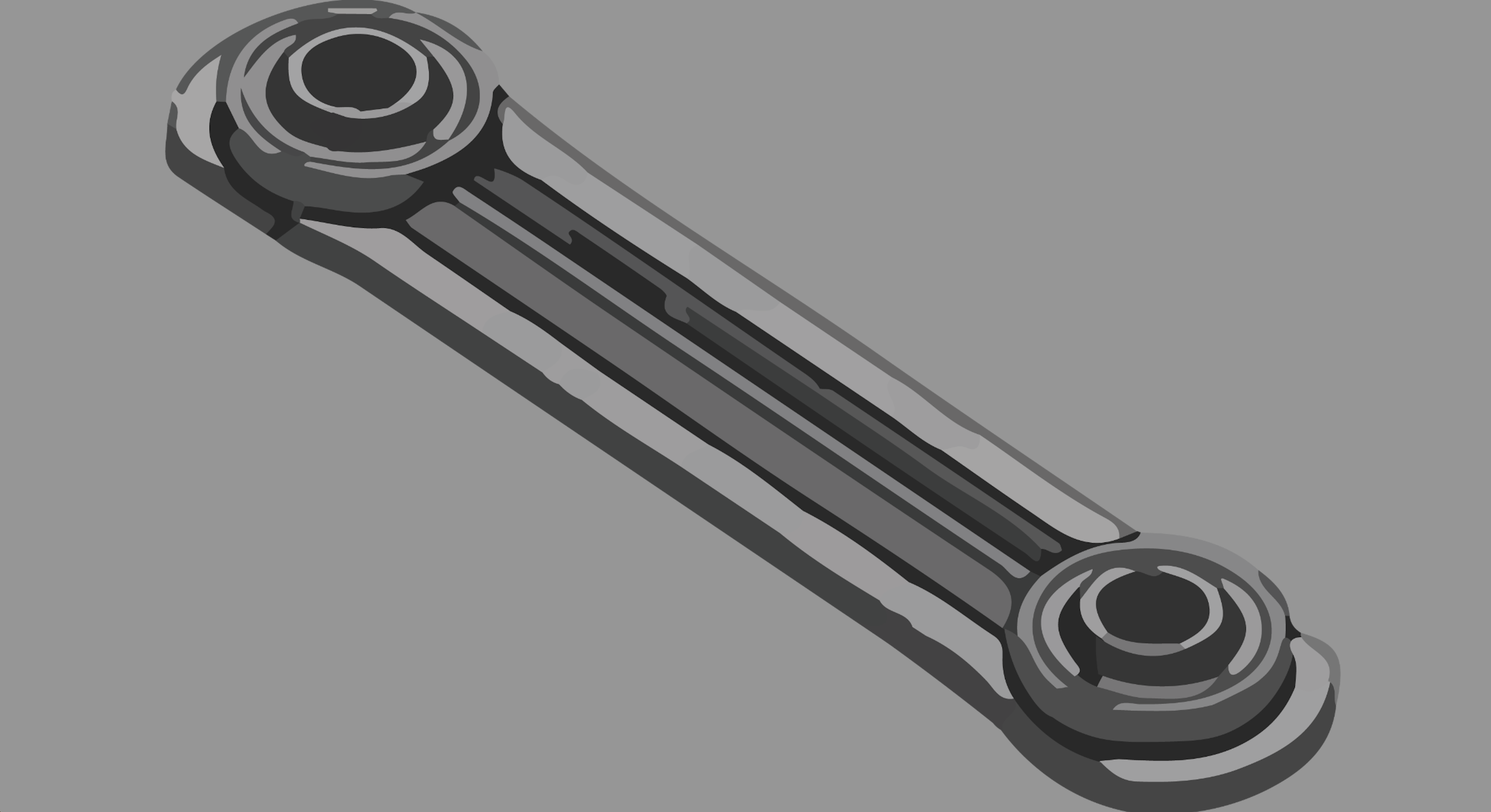

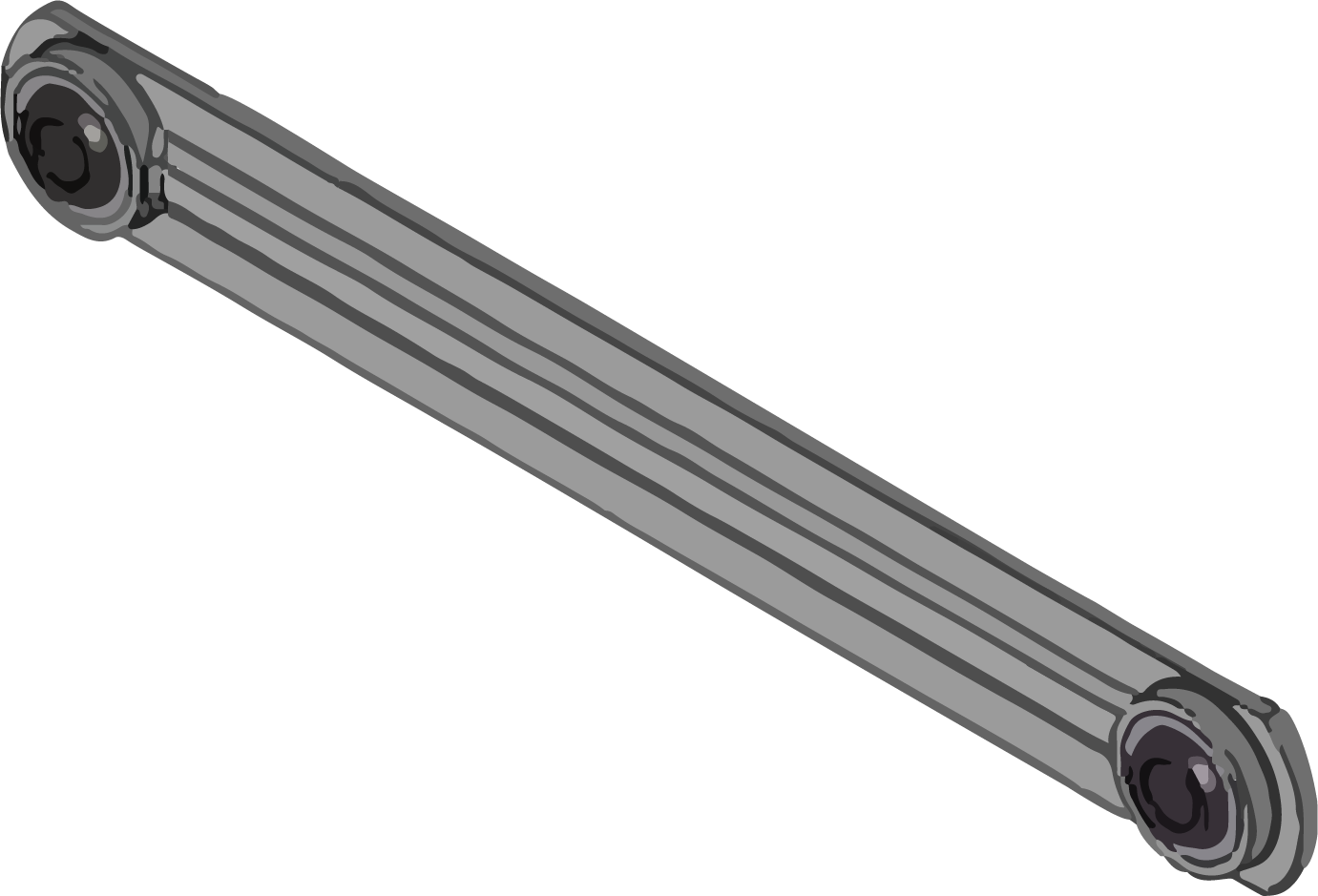

Triangle's Metal Linkage Assembly

One of Triangle's application engineers suggested the use of a metal linkage assembly. Triangle's linkage assemblies are stamped from galvanized steel and manufactured with a rib in the middle. This adds more strength to the metal linkage at a reduced thickness.

Another benefit to Triangle's linkage assembly is that it is manufactured with two spherical plain bearings. These bearings are self-aligning which will help the linkage assembly align when it is moved around during operation. Triangle's spherical plain bearings are self-lubricating which reduces noise and results in less maintenance.

The Turf Equipment Manufacturer switched to Triangle's Metal Linkage Assembly which resulted in:

- Cost-Savings

- Reduced Assembly time

- Improved Application

- Lower Maintenance

Triangle's metal linkage assemblies are custom made to fit each application need. They are available with different spherical plain bearing materials such as sintered bronze, sintered iron, chrome steel or molded nylon. If you are interested in a custom linkage assembly, contact us today. We would love to hear about your application.